2007

2007

The steering system

by Johan Kjellander 2007, 2014

December to February

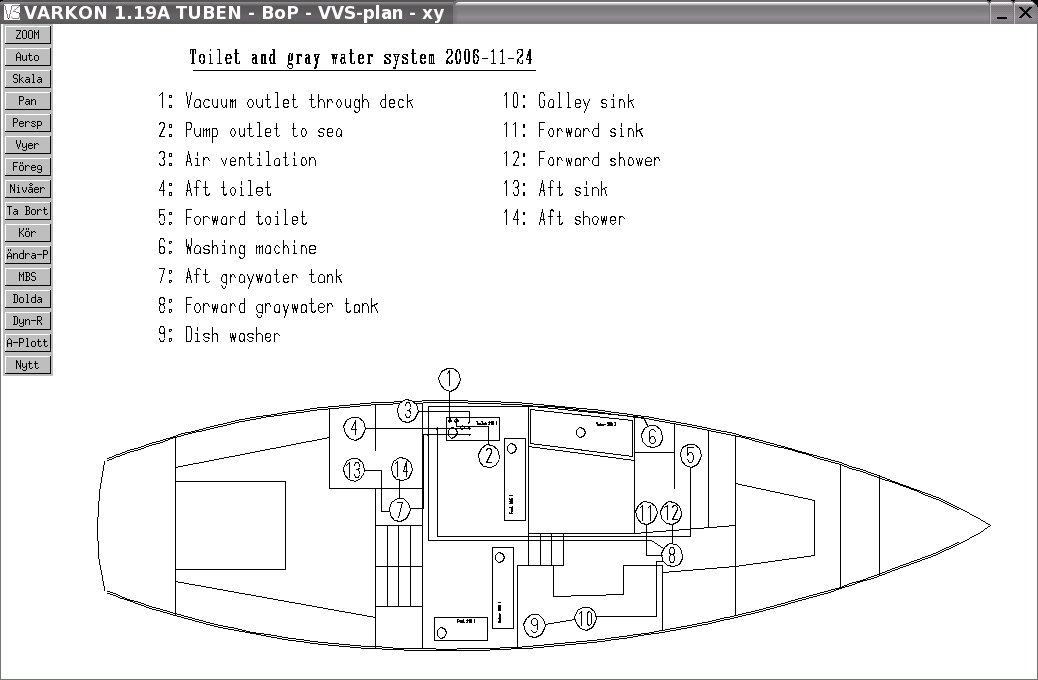

During december I finished the planning of the fresh-, sea- and waste water system and with all tanks finally in position I could now order toilets, pumps and all the different hoses needed. Above is a drawing showing the layout of the toilet and gray water system. Since I live close to Örebro where the main factory of Johnson Pump is located it was quite natural to go for Johnson. I ordered 2 electric toilets (AquaT Premium each with 2 pumps), 1 pump for emptying the toilet tank (Viking 32), 2 gray water pumps (Viking 16), sea water pump (5 kg pressure), fresh water pump, bilge pump (L4000) and a spare pump for circulating the hot water in the heating system, all from Johnson. 11 pumps in total !

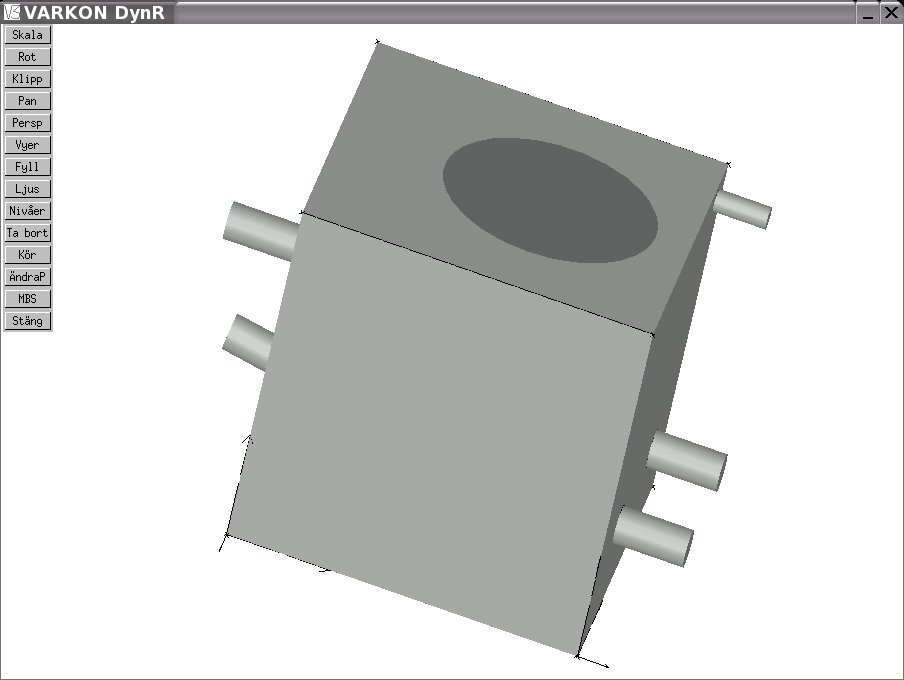

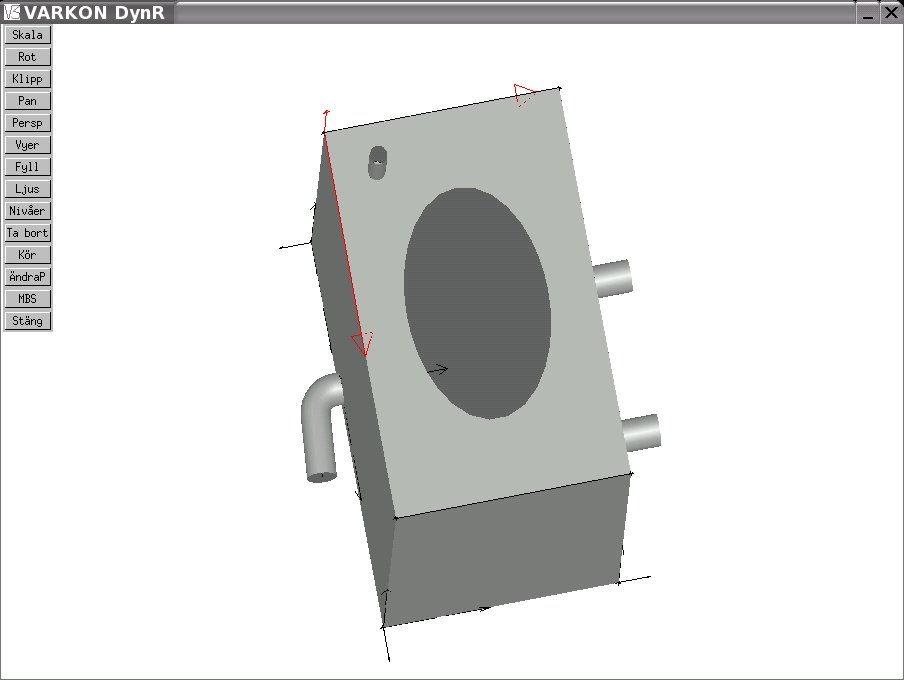

I also need 2 gray water bilge tanks, one forward and one aft, but I have not found any that fit well so I decided to design them myself, see CAD models above. The drawing in the previous paragraph shows where they will fit. Each tank will have an electronic level sensor inside that will start the pump automatically when the gray water level reaches above 50 mm.

Another job coming up soon is windows. I need 11 windows for the deck house and I want them to be of double glass for good heat insulation. I received an offer from a company in Norway on windows. They make very nice windows, even windows that open and the quality seems very high. So is the price ! A low budget version would be to bye only the glass and make the frames by yourself. My search continues....

Main job for 2007 is the rudder. So far I have CAD model and I have bought some of the material. Rudder stock is a 1.6 meter long stainless tube 80 mm outside and 63 mm inside.

March to June

Gray water bilge tanks are now finished and in position. One forward and one aft. The forward tank has 3 inlets (shower, handbasin and galley) and one outlet connected to a Viking 16 pump controlled by an electronic level sensor inside the tank. It also has air ventilation. The lid is transparent to make it possible to inspect the inside without opening the tank. The aft tank is more or less identical and will take care of the gray water from the aft shower and handbasin. It is placed under the floor of the machine room together with the fresh water pump, the sea water pump and the main bilge pump.

The gray water from the two tanks/pumps will go to a 2-way manual valve where we can select between letting the gray water go directly to sea or to the toilet tank. The toilet tank will be possible to empty from shore through an outlet on deck or with a pump (Viking 32) to sea.

Other jobs currently under work is an electric fan for ventilation outlet above the stove in the galley.

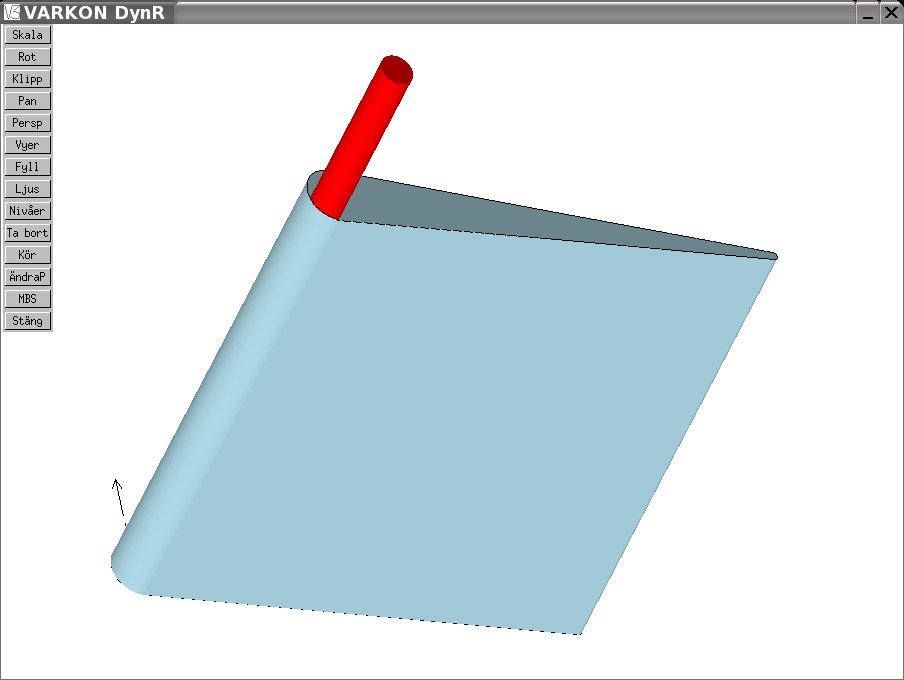

Work with the rudder stock and bearings has begun. Here is the hole in the keelplank for the main bearing.

The aft bearings for the propeller shafts are now in position.

Yesterday i got an old truck wagon delivered to the boathouse. The plan is to rebuild it so that it can be used to transport Bird of Passage to the port in Örebro, a trip of approximately 30 kilometers.

At the same time I also received the lead keel from a wooden sailboat that was in such a bad shape that the owner decided to let it burn to ashes. The weight of this keel is more than a ton, maybe one and a half. Together with what I have collected earlier I now have about 2.5 tons of lead. I still need two tons more !

Well that's all for now. I'm aware of the fact that the time since the previous update of this page is longer than ever before. I have received several e-mails about that and some of them also express worries that I'm giving up this huge project. I do admit that each day is getting tougher and tougher but at the same time we now see the end of the journey and that helps a lot. Thanks for nice e-mails.

One way to get the spirits going is to take a short holiday and do something else. In the end of February we went for a one week holiday to Sharm el Sheik in Egypt. All four of us went for coral diving in the Read Sea but also visited the St. Katherine monastery at the foot of the Sinai mountain and the famous pyramids in the desert outside Cairo. Guess what I found close to the biggest of the pyramids ? A boat of course ! In the middle of a desert ! Well, the story is that in the old times the river Nile flooded for three months each year and the water then raised to a level that made it possible to sail all the way to the foot of the pyramid. This was how the building material was transported when the pyramids were built. Then the great king Cheops died and his body was taken to his pyramid in a boat that was disassembled and berried in a grave of it's own by the foot of the pyramid. The boat was built in Ceder wood from Lebanon, 40 meters long and was found less than 100 years ago. A museum was built over it's grave and the boat is now reassembled inside the museum.

This is the oldest boat in the world, 4600 years and still in good condition !

To the left is picture of a model. The two other pictures show the real boat. The right picture is a close up of the stern.

July and August

A lot of time this summer has been spent on the old truck wagon. The wheels have been removed to make it possible to remove the suspension and thus lower the wagon about 35 cm. I also need to lengthen the frame 1.5 meters.

My oldest son is now big enough to give me a hand and that helps a lot. My old tractor is also a big help when it comes to heavy lifts.

Many things inside are now more or less finished. Here is a picture from the aft toilet. Not very much left to do.

Here is a picture from the galley. The stainless ventilator with it's electric fan over the stove is now mounted.

Finally a picture from the stern where the outside shower is now mounted in it's box.

Next in turn is to mount the windows. I have ordered 11 windows with double hardened glass (6 + 4 mm). Hope to be able to show the result soon. I'm also waiting for the last machining of my rudder stock so that I can mount the rudder stock bearings. The rudder itself will not be mounted until the boat is in the harbor ready to launch. With the rudder mounted the under water body becomes 1.2 meters longer and this means that the wheelbase of the wagon needs to be 1.2 meters longer which I don't want. It's very long already. Cutting corners in the city of Örebro might become difficult.

September to December

Finally the windows are mounted. Double hardened glass (6+4 mm) for good heat insulation and security. Stainless frames will be added later on the outside.

Another job that is finished is the showers. Above is the aft shower.

The main issue during this period has been the steering system. Rudder, rudder bearings, hydraulic components and autopilot system. I finally decided to make the rudder stock from a 1.6 meter long stainless tube with outside diameter of 80 millimeters and inside diameter of 63 millimeters. It was not easy to find someone with a machine big enough to do the turning of the bearing surfaces but eventually I got the job done. An upper bearing house with radial bearings is mounted through the keel plank and there is also a lower bearing house mounted to the bottom of the keel. These two will keep the rudder in place. To take the axial load an axial roller bearing is integrated in the upper bearing house. Inside the boat, under the bed in the aft cabin, a lever will be mounted on the rudder stock and a hydraulic cylinder connected to it.

The size of the rudder is 1.2 X 1.5 meters. With an estimated cruising speed of 8 knots this gives a calculated maximum rudder torque of approx. 3.3 kNm. This requires a heavy steering cylinder that you will normally only see on fishing boats and similar. I ordered a CTC300 steering cylinder and a P63S steering pump from Italian BCS through their Swedish representative ItalNordic. Expensive things but probably the best you can get. The steering pump will be mounted on the outside steering console.

There will also be an inside steering position through the autopilot/servo system. I spent a lot of time this autumn to investigate different auto pilot systems. The size of the boat (and rudder) requires a really big electric servo pump for the hydraulic system. There are big pumps available from several suppliers (BCS included) but they are of a type that requires that they run constantly. This is only possible on a motor boat where electricity is available “for free” as long as the engine is running. On a sailing boat you need a reversible DC servo pump that only operates when it is needed. I finally found one big enough from Simrad.It's name is RPU300 and it will be controlled by a Simrad autopilot system with rate gyro compass, rudder angle sensor, main computer AC40 and two AP25 control stations, one inside and one outside. The inside AP25 control station can also be used to steer the boat manually through the RPU300.

Another job that has now started is finishing the inside ceilings. There is 20 millimeters of heat insulation on the inside of the deck everywhere and to cover that there is sheets of 6 millimeter plywood treated with epoxy to be waterproof.

The job now is to cover these plywood sheets with a nice looking PVC film with 3 millimeters of PVC foam on the back side. I use a water based glue from Casco. I have bad experiences from water based glues before so I'm a little bit nervous but I think these glues have become better than they were some years ago. Wish me good luck!