Buildning a Guyline 125

Buildning a Guyline 125

by Johan Kjellander 2014

First year, 1984

By the end of the season 1983 I sold my trawler Etoile. After 5 years with a motorsailer I felt it was time for a ¨real¨ sail boat. Somebody told me to take a look at the Guyline 125 and that was it, I fell completely in love. Early spring 1984 I got the opportunity to sail one for a few hours in Stockholm and after that I mailed my order.

Here is a link to a brochure from 1984 (in Swedish language).

Guyline 125 was manufactured by Bröderna Börjesson in Bjästa, close to Örnskjöldsvik in Sweden. I asked them if they would sell me an empty hull with engine installed and they said yes. At the same time I ordered a complete rig from Selden in Gothenburg and two sails from Rolf Magnusson in Karlstad, everything to be delivered to Börjessons factory in Bjästa. Her sail number was S14 and I named her Lynx.

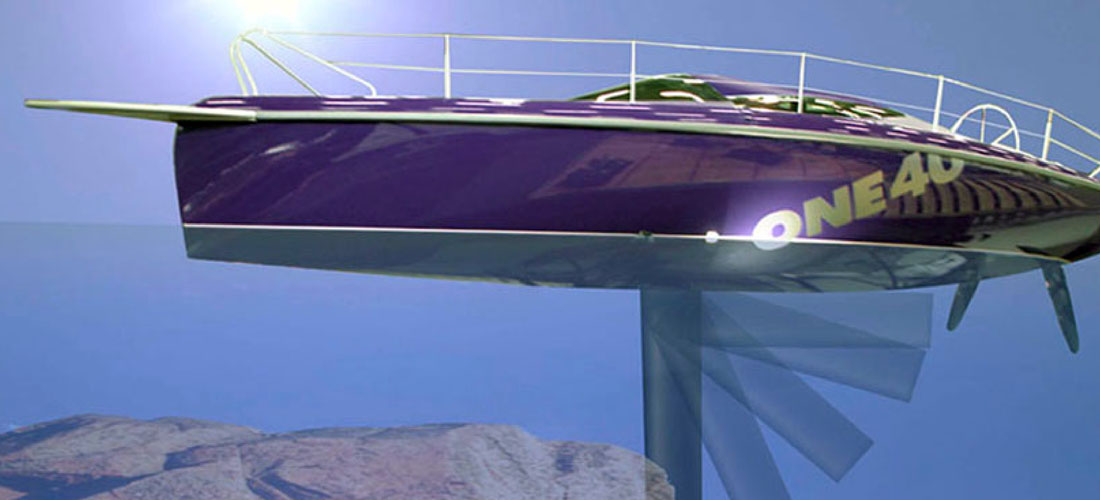

The 125 was the largest Guyline of three, designed by Guy-Christer Lönngren from Åbo, Finland. There was also a Guyline 105 and a Guyline 95. Before the Guylines, he designed Lohi 25, Guy 22, Guy 27, and Guy 33. Later there was Guyline 3800, Guyline 822, One 40 (above), Go 5 and so on. A very productive man, who has always liked the futuristic look. Today he is involved in the design of floating houses. Here is a link to his website.

In April I went to Bjästa with car and caravan to start working with Lynx while she was still inside the factory. I met Gerhard Stenberg who I had contact with earlier and also P.G. Forslund, the managing director. All very nice people. I stayed for a week and worked hard to get her ready to be moved outside. The plan was to come back in June and do the rest of the jobs needed to get her sailing and then take her home to Örebro by sea. The picture above is the first picture I have of Lynx. She has no keel, no rudder and she is completely empty inside. Topsides and deck are balsa sandwich GRP. Below the waterline the hull is single skin GRP. A stiffening GRP liner is laminated to the inside of the hull. I only needed to add 4 plywood bulkheads to make her strong enough to be sailed home to Örebro.

I returned to Bjästa by the end of May. I worked hard for a week to get her ready for launching and by the 6:th of June she had her first contact with water in Näske harbour in Bay of Botnia. After a few days of rigging and final fixes my youngest brother Petter came by train to take the car and caravan back to Örebro and I moved into Lynx. Not very comfortable in a completely empty boat smelling polyester and diesel. On the 12:th of June I left the harbour to sail south. No guardrails, no windows, no tanks, no galley, no toilet... She was fantastic in light winds, see above. You can read more about this virgin trip in the Cruising log of 1984.

Work continued every winter

For many years I sailed every summer and worked inside the boat in the winters. Slowly, slowly she was more and more completed. The first job of course was the heating system. Water based central heating, a 20 litre hot water tank for the shower with an electric heater but also a Reflex Diesel heater connected to the system and a 12V pump to circulate the water through the radiators.

This heating system worked fairly well for many years. The Reflex is quiet and does not need electricity. However, you can only use it in harbours or extremely calm seas. In rough seas, sooner or later she will extinguish with heavy diesel smoke coming into the boat. If you were not seasick by then... I remember that this was a big disappointment because I had put quite a lot of job into the installation. Even with a 2 meter long chimney and a H-cap on the top the Reflex would not cope with rough seas or turbulent wind.

Another big project the first winter was windows. The Guyline 125 has three planar windows facing forward and one long curved window on each side of the deck house. I talked to Ö-Metal north of Gothenburg and they agreed to make me three thermo glass windows and two longer windows in single glass. The single glass windows could easily be bent to fit the curved shape. The three windows in double glass facing forward showed to be a success. Very little condensation inside on these windows and much more on the single glass windows. Here is a link to Ö-Metal.

Each winter I continued the work inside and each summer I sailed, longer and longer. Tove joined me on the trip to Iceland in 1987 so from that year we were two. It took many years to complete the inside but after ten years when we left Sweden to sail south for the Mediterranean she was more or less completed. We had then also extended the length of the boat from 12.5 meters to 14.35 by adding a new piece of hull to the stern. This was a big project that we did during the summer 1992. You can read all about it here !

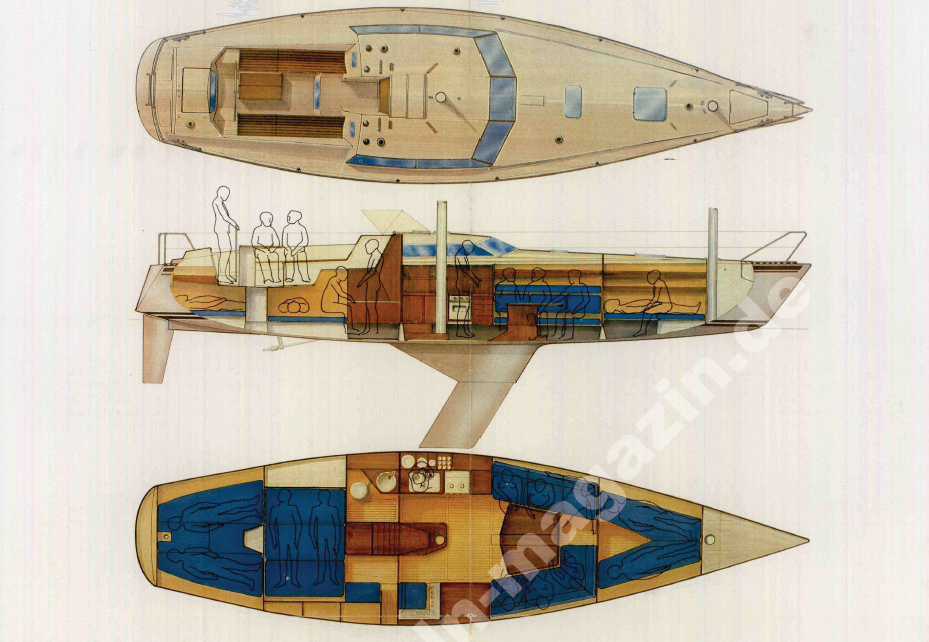

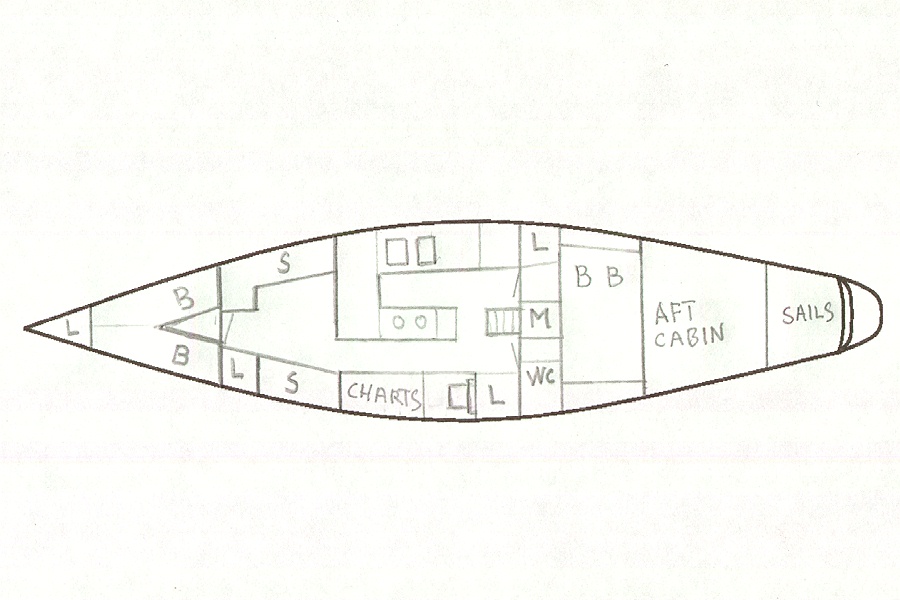

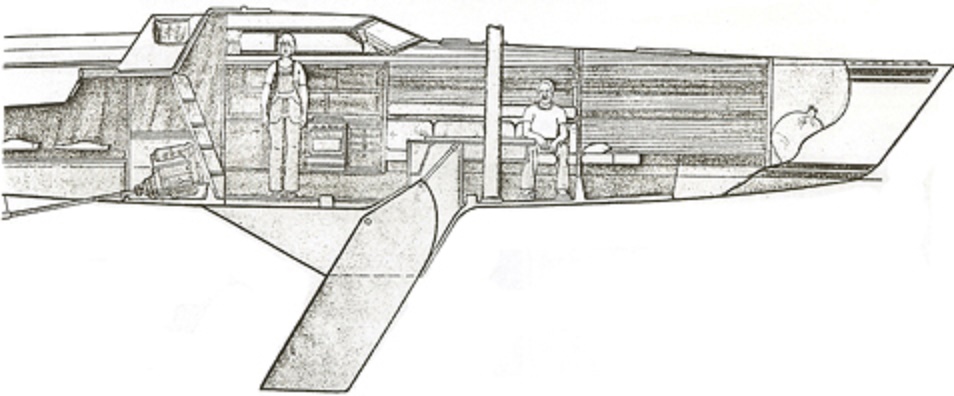

Accomodation

Above is the interior layout of Lynx after I extended her to 14.35 meters. L=locker, B=bed, S=sofa, M=motor. The aft cabin is normally used only as storage. It accommodates 2 full size bicycles, an outboard motor, diving equipment, a small washing machine, extra diesel and water tanks, food for many weeks and lots of extra stuff. The last piece of the hull was storage for sails, toilet paper and other things that were not too heavy.

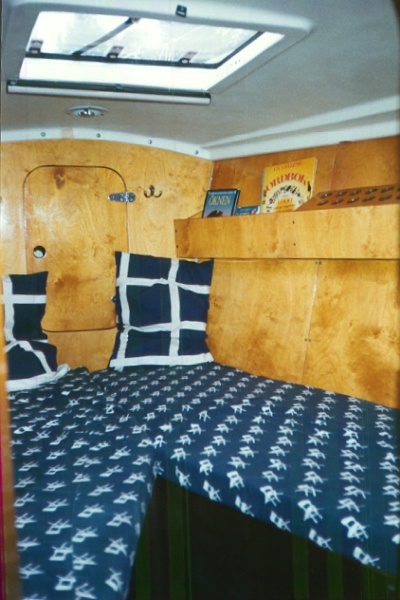

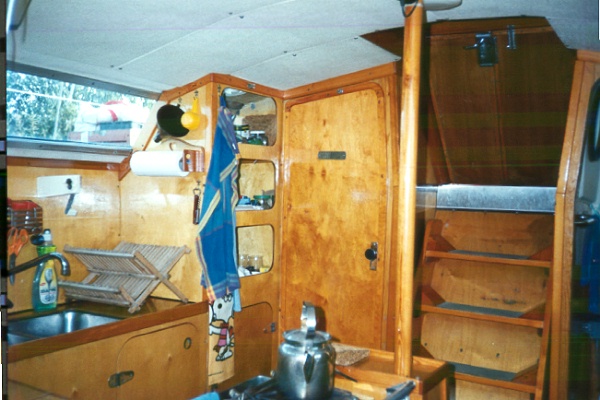

The centre cabin includes a double berth, a large and a small locker and plenty of bookshelves. This was Tove's and my cabin. Up to the left in the left picture you see my two black cooling fans that pumped air from the cockpit into the cabin during hot nights. Simple but very effective.

The fore cabin sleeps 2 and also has a locker. This is where our children, Martin and Gustav had their headquarters. I used birch plywood everywhere and treated it with tint to make it more sun resistant.

The saloon includes a L-shaped sofa on one side and a smaller sofa and a locker on the other side. The saloon also includes a large table for 6 in the middle. The big sofa can be used as an extra berth but the small sofa is only 1.4 meters long. It can be used as a berth by a child.

The bathroom includes a large sink for washing, hot and cold fresh water as well as sea water from taps fed by electric pumps. The toilet is a Baby Blake. There was no holding tank installed.

The shower is thermostatically controlled and an electric bilge pump takes care of the graywater.

The U-saped galley includes 2 sinks, hot and cold fresh water and an extra tap with seawater. An Origo alcohol cooker with 2 burners on top and one burner in the owen. The entire cooker with owen is mounted on swinging taps and can be used while sailing.

Opposite to the galley was a large wet locker...

Navigation

...and the navigation table with instruments etc. and a chair. Under the chair is a 25 litre cooling box with a Supercool 12 volt refrigerator.

In the cockpit I had a 150 millimeter Silva compass, a VDO electronic log and a VDO depth sounder. There was also a control panel for the autopilot (Autohelm 6000) and the Volvo Penta engine of course. When sails were set you could turn on the autopilot and move inside to the chair behind the navigation table keeping watch through the glass windows. I also had a remote control for the autopilot there, so I could alter the course quickly if that should be needed. The inside control panel that you see on the middle picture above includes various switches and fuses for instruments, lanterns, lights and pumps etc. On the left picture you can see the Nekon NAVTEX receiver with printer, connected to an active antenna on the rear pushpit. On the right picture above you see a white Marinex VHF station, you also see the control panel for the fridge and the control panel for the ICOM 706MK2 ham radio. The Marinex had its antenna integrated with the Windex in the top of the mast and the ICOM used one of the aft stays as antenna. In the mast top there is also an anchor lantern and a combined 3 color sailing lantern. An extra set of more powerful lanterns were mounted on the pulpit, mast and pushpit.

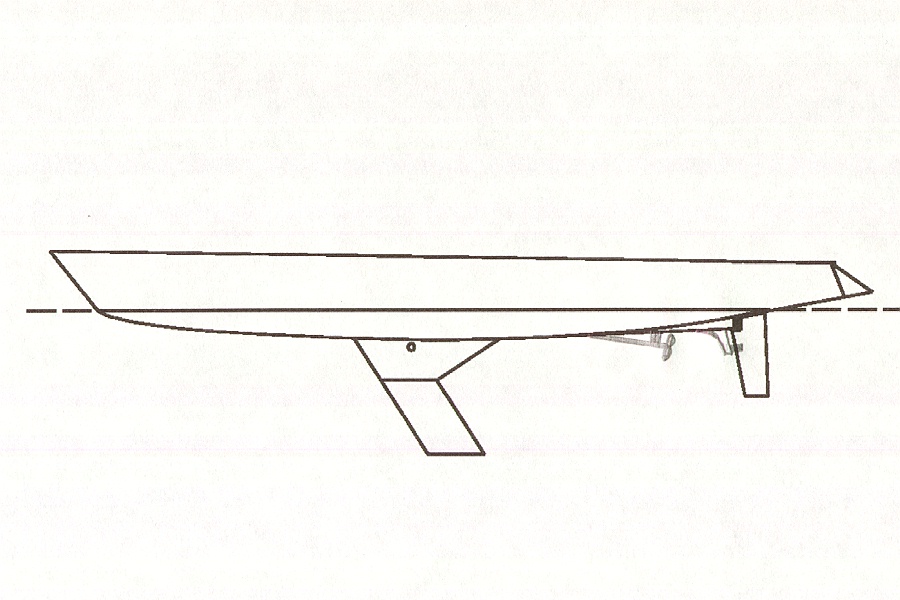

The swing keel

All the Guylines have hydraulically controlled swing keels. On the Guyline 125 this meant that you could reduce draft from 2.4 meters to 1.4 meters. Very practical, specially if you have your boat in the shallow harbour of Örebro (which we had). It can also be used to increase speed during downwind sailing or motoring and it reduces the risk of hull damages if you hit ground, because the keel folds back and takes some of the impact energy. If you are lucky you will just glide over the shallow and then the keel slowly comes down again. This happened to us several times.

The swing keel is a great idea and the concept as such has proved to work well. However, having two tons of lead hanging under your boat requires a very tough mechanism to move it up and down and to keep it in position. In rough seas the hull moves around quite a lot and the keel has to follow those motions. This was one of the weak sides of the Guyline concept. After our trip back to Sweden from the Mediterranean 1988 the keel had moved back and forth so much that it had damaged the hydraulics that were supposed to lift it. Corrosion was another issue. In warm salt waters even high quality stainless steel needs protection. There were no zinc anodes mounted on the parts under water and after some years we had an oil leakage because of corrosion that made it impossible to get the keel up. With the keel down you are too deep to go into many harbours or marinas. Two times during our time with Lynx we had to take her out of the water and remove the keel to repair the hydraulic system. This of course is not acceptable.

The rig

The standard rig for the Guyline was a 7/8 partial rig with swept back spreaders. In my opinion this is not an optimal rig for ocean cruising so I let Selden mast in Gothenburg design a masthead rig with straight spreaders and double aft stays. As far as I know this Guyline was the only one with a rig of that kind. The mast was 15 meters long and stepped on deck. Boom was 5 meters. Single pair of straight spreaders, 8 mm stays, double aft stays, both with double HF/SSB radio antenna insulators. Sails were from Magnussons sails in Karlstad. The main included 3 reefs of which 2 were controlled from the cockpit. The jib was self tacking and fitted on a Hood seafurl system. All lines were lead through Easylock clutches to Andersson stainless winches in the cockpit. She was very easily sailed by one person and there was normally no need to go up on deck. The main and the self tacking jib had a total area of 70 square meters which is well enough even in light winds. I had no genua but I had a 120 square meter asymmetrical spinnacker for some time but a sail like that needs a crew of two and is therefore not suited for short handed long range cruising. After a few years I sold it.

The machinery

The engine was a 36 hp 3 cylinder Volvo Penta MD17 Series 3000 from 1984. It worked fine for more than 10 ears but then it was over heated due to calcium growth in the cooling system. It only had sea water cooling so in 1997 I renovated it with new bearings, cylinders, pistons, lifters, injectors, pumps, generator etc. and a new fresh water cooling system. The shaft was 30 mm and the propeller a 3 blade sailing prop of the type where the blades rotate between forward and reverse and stay parallel to the water stream when sailing. Maximum speed under motor was 8 knots. At 7 knots she consumed 0.6 litres of diesel per nautical mile and at 6 knots less than 0.5 litres. With 220 litres of diesel in two different tanks she could do almost 500 nautical miles by engine.

Electricity

The main battery was a 200 Ah Sonnenschein gel battery. It was charged by the generator on the motor through an automatic switch that separated it from the 70 Ah motor battery when the motor was not running. It could also be charged by 3 solar panels of 50 watts each located on the rear pushpit or by a 230 volt 15 A automatic 12 volt charger. There was also a 1 kW solid state 12 volt DC to 230 volt AC inverter installed. The main electric control panel had a VDO voltmeter and a VDO ampmeter. 230 volt shore connection was done through a cable installed in the forward anchor box. The 230 volt shore line was permanently connected to the battery charger and water heater but there were also terminals at several places in the boat where you can connect any type of 220 volt equipment.

Anchoring

The main anchor was a 15 kilo original Bruce with 50 meters of 8 millimeter chain. The windlass was a manual Lofrans Royal, see here. The rear anchor was a 15 kilo Danfort type with 50 meters of 16 millimeter Marlow braid.

Here is one of the last pictures I have of Lynx, taken in Örebro harbour early summer 1999, short before she was sold.

Some technical data

| Length | 14.40 m |

| Beam | 3.26 m |

| Draft | 1.4 - 2.4 m |

| Weight | 6 tons |

| Height | 17 m |

| Main size | 40 m2 |

| Jib size | 30 m2 |

| LYS rating | 1.24 |

| Engine | VP 36 hp |

| Diesel | 220 litres |

| Water | 350 litres |