2009

2009

The Launch

by Johan Kjellander 2009, 2014

January to March

Motor installation is now more or less finished. Here is a picture of Sixten (the starboard motor) with control cables for speed and gearbox (dual station), exhaust, cooling, fuel, 12V etc. attached. Most of the equipment that I bought fitted well, but some of the things did not. Dual station system for two motors shouldn't be uncommon, but so it seems. The speed control on the Volvo's were made for single station and the Morse dual station stuff I bought didn't fit the Volvo. So, two days of welding, grinding, testing etc. and then everything was all right. I wonder how many times I have bought things that don't fit. Somebody is making a lot of money on us backyard builders !

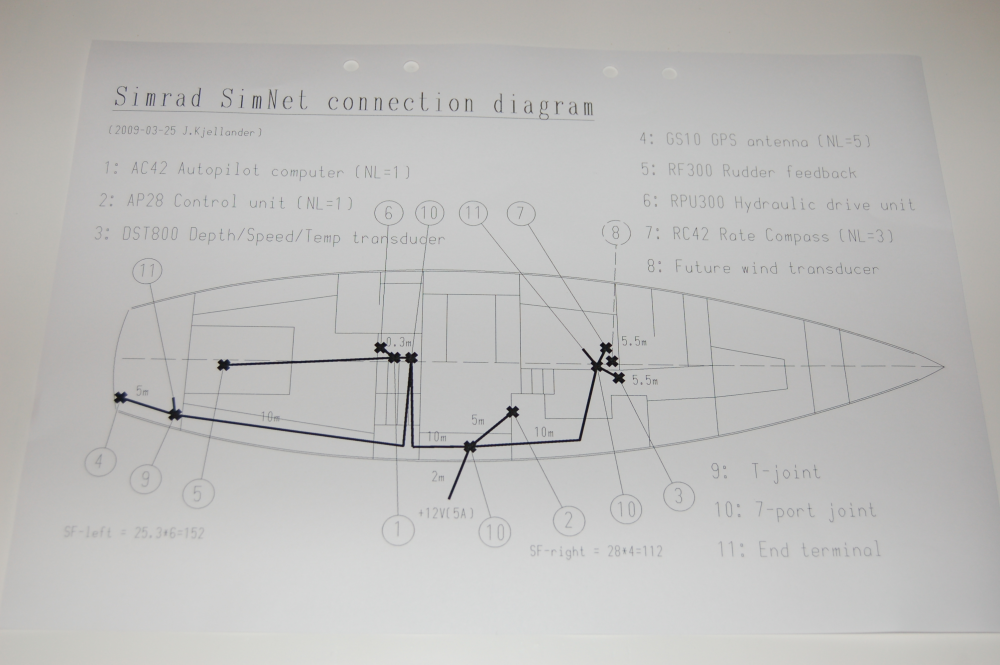

The navigation table is now finished. Two Volvo control panels and in the middle the Simrad AP28. I chose Simrad because they seem to be making equipment that fits bigger boats better. For one thing, they have the biggest hydraulic pump available. Many commersial vessels have Simrad systems.

Above is a connection diagram showing the entire system. It includes the AP28 auto pilot and its computer, the AC42 to the right, mounted in the engine room.

The AC42 can regulate up to 30 Amps of current to the hydrualic pump motor. The Simrad system is connected through a CAN bus system called SimNet and it talks NMEA 2000. This means that you can connect many things from different suppliers. The speed sensor to the left, also includes a depth sensor and a water temperature sensor. In the middle is the rategyro compass and to the right is the GPS reciever. Things that will be added in the future are wind data and a second AP28 or AP24 outside. The Simrad stuff is expensive so some things will have to wait.

If everything works out as planned we may be able to take a trip with Bird of Passage this summer, without the rig though. If so, we will need a working galley and for that reason we have now installed a fridge and a freezer. They are two separate units. The idea is that the freezer can be turned off when not needed to save energy but turned on again when the god of fishing is smiling at us. 50 litres of freezer and 65 litres of fridge. The fridge, btw also includes a small freezing compartment so that you can make ice for your drinks without having the big freezer turned on.

A nice kitchen might not be enough however to make the crew (our sons) happy. Internet is a must, so I got hold of a 12 volt USB network router and a USB 3G modem. The router distributes the network to the three cabins through shielded cables with RJ45 connectors but it also has a WIFI interface so that computers with WIFI can connect anywhere on the boat, probably also on the beach if the distance is not too long. We have tested at least 50 meters and that seems to work fine. The white stick on the picture is the USB 3G modem. The speed on the countryside where we live is around 0.4 Mb/sec but in places where UMTS is available, the speed is approx. 10 times higher. Right now it uses a SIM-card connected to Three, a Swedish phone company. When traveling abroad we will have to bye SIM-cards with other network providers. The USB modem has a connector for an external antenna that can be used to increase the reception in areas with weak signals.

April to May

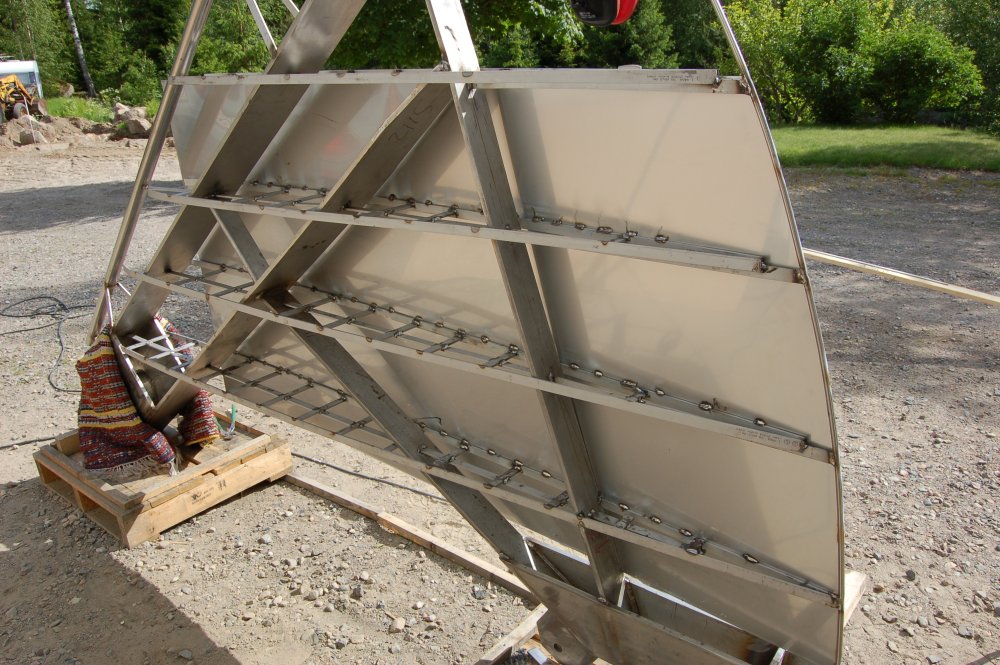

Launching is close now, one or two months left. Only one big job to do and that's the retractable ballast keel. Four tons of lead inside a stainless sheet metal mold with a strong internal structure also in stainless steel to keep everything together. Together with the keelbox the total weight of the ballast (fixed and retractable) is around 5.5 tons which is 40% of the boats displacement. Quite a lot of ballast for a modern boat. On the other hand she will be stable and sail well with moderate heeling. The calculated rightening moment RM is 113 kNM at 30 degrees of heeling which is relatively much for a boat with a design displacement of only 13.6 tons. Above are some of the parts that will make up the retractable keel structure. The diameter of the keel pivot is 90 mm.

I have been collecting scrap lead for many years now and some of it is car wheel balance weights. These need to be melted and cleaned from steel clips before they can be used. For that purpose we built this primitive furnace heated by a wood fire. To form lead bars you need some kind of molds, aluminum boxes work but steel is better.

Here is the result, 300 kg's of lead bars. The only thing left are the steel clips. You can see more pictures from the lead melting here. To melt all the 4 tons of lead for the keel a larger furnace is needed so we have now built this monster that we hope will be able to melt at least one ton of lead at the time. We will probably try it out with some larger pieces of scrap lead later today.

Now to something completely different ! Locks are very much psychology. Hope it gives an impression that breaking in is not too easy. Let's also hope I never loose the key.

The electric system is now more or less finished. Latest additions are two 200 Ah AGM batteries and a Victron charger/inverter. To keep an eye on the voltage I bought a relatively sensitive voltage sensor with digital display and mounted it in the deck house where it is easy see. Next year I will add solar panels to the system.

A final picture shows the GPS sensor mounted on the pulpit. This is a temporary solution for this summer. I want to be able to test the Simrad navigation system with the GPS connected. Next year I plan to build some kind of mast for all antennas (GPS, AIS, NAVTEX, TV, GSM/UMTS etc.) and a future radar as well.

June

The keel is finished now ! FirstI dug a big hole in the ground ! Thanks Kjell for borrowing your machine.

Then I welded and welded and welded.

After that I covered the structure with 2 mm stainless sheet metal. All metal is 316L or EN 1.4404 with 2% molybdene. Expensive, yes but more resistant. Then down into the ground stuffed with fine sand all around.

Now the bathtub was filled with lead. The lead on this picture is from an old sailboat keel. It will now live another life in Bird of Passage.

The furnace was filled with wood and melting started. 4 tons of lead was melted in 6 hours. One ton at the time.

Some pieces were bigger, but they melted just as well. Finally, we let the lead down into the keel. Tomorrow we will prepare for launching. The plan is to take the boat to the harbor separate from the keel and fit the keel just before launching, hopefully in a few days from now.

At the same time I want to say some words about Johnsson Pump equipment. The company is in Örebro, Sweden, 30 km's from where I live and I even have had some cooperation with them through my job at the University. I bought all pumps in one purchase through their dealer Comstedt in Gothenburg 2 years ago. First thing I noticed was that one of their automatic level switches for gray water was broken. I phoned them and they asked me to send it to them and after a while they sent me a new. Ok, bying equipment for almost 30' SEK, one thing might be broken. Then I started the system, and one of the gray water bilge pumps (a Viking 16) was leaking water due to a crack in the plastic pump house. Calling Comstedt again they didn't want to replace this so I had to pay 600 SEK. Finally after two days of operation, the second level switch stopped working. I dismounted it and it showed to be full of water ! Please explain to me how a Swedish company can manufacture products made for under water operation (the level switch) that are not water proof ? I'm sorry about this as I live close to the company but I must warn you all about Johnson Pump equipment. The quality in my opinion is well below what you would expect.

July – September

After a few days of preparations we finally started the 30 km long trip to the harbour in Örebro. We used a 5 ton tractor for pulling and a car with warning lights and signs. There was not much room to begin with.

The highest part of the boat was 4.75 meters above ground. Normal clearance on Swedish roads is 4.50 so we had to check every bridge and every cable crossing the road to assure that we would pass. In some places it was tight but everything went well. Here is a nice picture with the Bird of Passage flying along the summer road. The rudder and the lead keel went to the harbor separately.

After having painted the bottom with antifouling it was time to call for the mobile crane. First thing to do was to mount the lead keel.

The boat was lifted and then lowered over the keel which was fixed in an upright position by a temporary support made from scrap metal.

Half way down the metal support was removed and the boat could be lowered to a position so that the keel bolt could be mounted.

Next thing was to get the rudder in the right position. Finally the two propellers were mounted.

After that she went directly into the water. The time was around 9 in the evening on friday the 26:th of June, approximately 9 years after I started cutting the first frames with my jigsaw. So many people have helped, specially these last days. You all know who you are and I don't know how to thank you. Here she is finally floating on her own keel and on the right picture she is doing way through the water (a few days later).

I also have two video clips, one from the road transport and one from the launching. Here they are:

Transport in mpg format(6.1Mb)

Transport in wmv-format(8.4Mb)

Launch in mpg format (5.2 Mb)

Launch in wmv-format (7.1 Mb)

Please let me know if you cant get them working.

Naturally, there were many questions now with the boat in the water. Did she float right? Were there any water leaks ? How did she perform under motor? And so on....and so on.... Well, the summer is now over and we have lived in the boat for 3 months and traveled almost 1000 nautical miles under motor (there is still no rig) so we have answers to most of the questions. It has been a fantastic summer and we are very satisfied but there have been problems and some of them are not yet solved.

The first surprise was that the scale in the mobile crane showed that she was 2 tons heavier than expected. According to Tom MacNaughton's original calculations the displacement should be 13.6 tons. After that I have altered the design slightly which has added weight so in my mind I have expected the displacement to end up around 14 tons. However, the scale on the mobile crane showed 17 tons ! I know I had one of the water tanks filled, all tools, books, food, clothes etc. etc. This makes at least a ton. So, empty boat would be 16 tons but should be 14. And then there is still no rig ! Being heavier than expected she also floated lower than expected, approximately 10 centimeters. Since each centimeter of immersion represents around 325 kg this makes 3 tons which is what we had, 14 + 3 = 17 ! So, there is probably nothing wrong with the scale on the crane, the boat is heavier than planned and the only explanation I can give is that I have used more material than needed and added more technical equipment than Tom MacNaughton expected. Central heating alone is at least 300 kg's. On the other hand, 13.6 tons for a 17 meter cruising sailboat is a very low figure. Similar boats the same size are usually closer to 20 tons so there is no reason to worry about the weight I should think.

It also showed that she floated approximately 10 cm lower on the bow than the stern. Too much weight in the forward part of the boat. I fixed this by adding 400 kg lead as low as possible in the stern. There is still a lot of equipment to be added so maybe some of this lead can be removed later.

It was now time to fill up the fuel tanks. At first everything seemed to go well but after 10 minutes I had diesel in the bilge. A quick investigation showed that one of the tanks was leaking, probably from the bottom. Only way to fix that was to pump out all 200 liters of diesel, dismount the tank, lift it up and check. Each of the plastic tanks from Vetus comes with a removable screw lid. Depending on how you mount the tank this lid may end up in the top of the tank or the bottom of the tank. Each way is ok according to Vetus but of course you need to check that the screw lid is tightened before you mount the tank, specially if it ends up in the bottom of the tank ! I must have forgotten this. With the tank lifted it was easy to tighten the lid, remount the tank and fill it up again. After that we have had no fuel leakage but keep on reading and you will see that there are worse things than fuel that can leak from tanks !

Both motors started easily and we made our first trip on the river leading to lake Hjälmaren. I pushed the motor controls forward to get the propellers spinning but as I pushed them more to increase the speed there was a terrible sound from inside the boat. My first thought was that it came from the propeller shaft bearings but slowly I became more and more convinced that the sound emerged from the propellers themselves. I had never heard anything like it, a terrible high screaming singing noise. A few days later after a telephone call to the propeller supplier I knew that I was one of the rare victims of a disease called “Singing propellers”, a phenomena which is technically not dangerous but very annoying to anyone with normal hearing. The cure is to change the geometry of the trailing edge of each propeller blade slightly with a grinder so that a chamfer is introduced that ensures that the flow around the blade is stable. This would require a lift of the boat to dismount the propellers, then sending them to the supplier, getting them back, lifting the boat again and remounting the propellers. A slow and expensive operation so I decided to live with the noise, at least for the time being. A few weeks later when we arrived to Åland I rented some diving gear and manually worked the blades with a metal file. The result was a big improvement but there is still some noise left.

Next disaster was worse. The black water holding tank started leaking ! This is the tank that takes care of the waste from the toilets. A terrible smell came from below and black water was pouring back and forth in the bilge. We emptied the tank, cleaned the bilge and started searching for an explanation. This time it was an inspection lid on the top of the tank that was not securely tightened. We did not recognize that the tank was full so a pressure was built up inside and black water came out through the inspection lid. My fault again ! We tightened the lid and since then we have had no more tanks leaking. On top of that we mounted a Gobius tank sensor to be sure to know when the tank is full.

With most of the initial problems fixed I made some tests to see how she performed under motor. The motors have a maximum recommended cruising speed of 2500 rpm. At 2500 rpm the boat speed is exactly 7 knots. At full speed, 3300 rpm, the boat speed is 8.5 knots. She runs fantastically smooth through the water leaving only minor waves behind at 7 knots and the fuel consumption at this speed is only 0.82 liters/nautical mile (0.41/motor). I have a strong feeling that we could increase the pitch of our propellers one or two inches and lower the cruising speed of the motors a few hundred rpm's or increase the boat speed at 2500 to 7.5 or 8 knots. The fuel consumption would then increase of course but sometimes an extra knot is very valuable on a long range cruiser.

We have now traveled almost 1000 nautical miles, most of the time at 7 knots. We have passed sea of Åland twice, we have experienced strong winds, with heavy rain, from various directions. Under all circumstances it has been a pure pleasure to be on board. We now live in the boat in Örebro harbor and life aboard is warm and nice even when the temperature outside goes under zero. This summer has been one of the most intense periods in my life. So much has happened and even if there has been initial problems the impression right now is that we have a fantastic boat. There is one more year to go however before she is fully completed. The main issue is the rig of course but there are a number of other things to do as well.

October – December

By the end of October the big mobile crane came to the harbor to lift some boats for the winter. We then took the opportunity to also lift Bird of Passage, remove the propellers and launch her back into the water again without propellers. The propellers needed adjustments to cope with terrible singing and wrong pitch. Even if Bird of Passage stayed in the water she would not need any propellers during the winter since the plan is to stay in the harbour and use the boat only for living. Leaving the boat in the water makes life aboard more comfortable in several ways. Even if there is ice, there is always water under the ice and the water temperature is usually higher than the temperature of the air. This saves energy (money). With the boat in the water, boarding is easy, you don't need to climb a ladder. Finally, getting rid of gray water is easier with the boat in the water than on land.

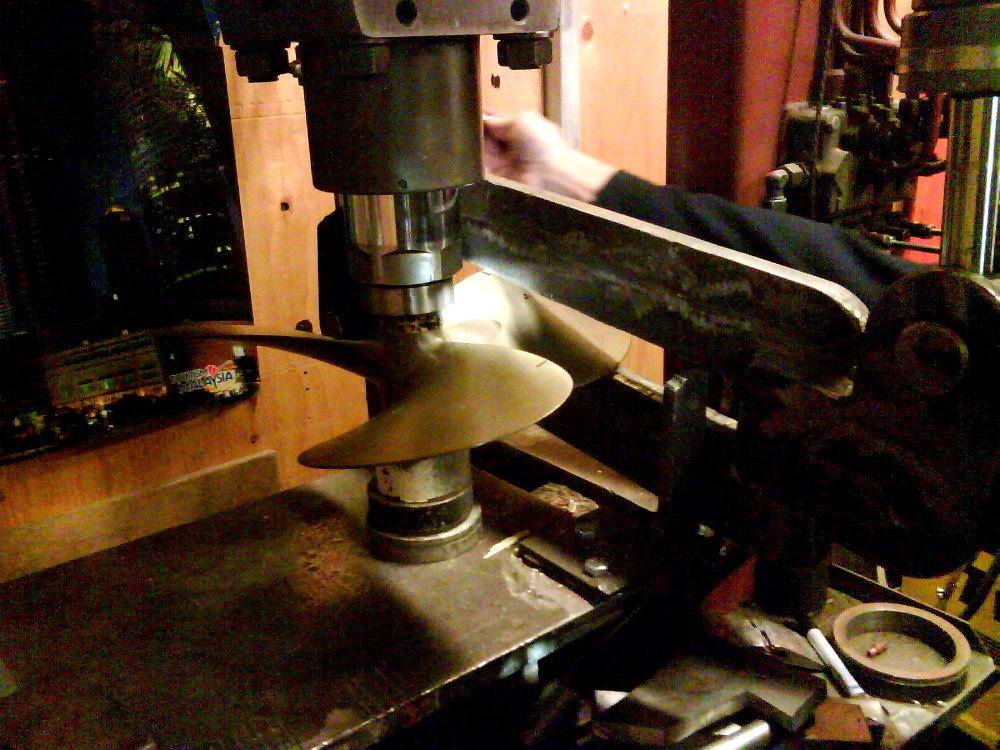

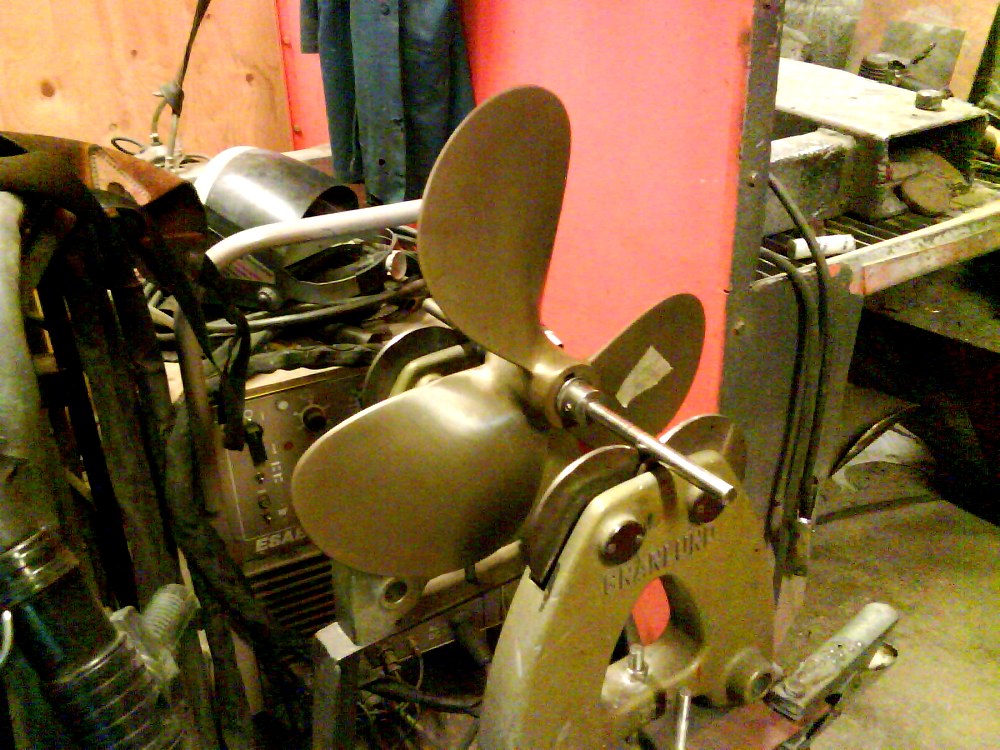

After some investigation I got in contact with one of the few persons in Sweden who has the right tools and the right knowledge to fix a propeller, a “Propeller doctor”. First he grinded the trailing edge of the blades to get rid of the singing, a so called “anti singing chamfer”. If you read the July-September blog below, you will see that I did a similar job under water with a metal file this summer, but the propeller doctor had an air driven grinder and was not disturbed by heavy diving equipment so I'm sure he made a much better job.

Then he put each propeller in a specially designed self made “hydraulic pitch adjuster”. With this machine he twisted the blades so that the pitch was increased by one inch. Finally he did what is usually called “cupping”. This means that he manually bent the trailing edge of the blades by hammering. A job for a real expert. Cupping increases pitch but also reduces singing. After this he tested the propellers for static balance. The final effect is that I now have two propellers with 1.5 inch more pitch and hopefully without singing. A friend of mine who is a very good diver was going to re-mount the propellers a few weeks ago but then the real winter came with 15-20 degrees below zero and thick ice. That job will have to wait.

Meanwhile I finished some jobs inside the boat. The galley now has an Electrolux micro owen and dishwasher. Having lived in the boat for almost 6 months now, I must say life is comfortable. It's very close to living in an apartment, but cheaper. The harbor fee for the winter season (November-Mars) is 2000 SEK + electricity. As I use electric heating, paying the bill for electricity is nothing I look forward to! The winter so far, has been very cold with a lot of snow and thick ice. Inside Bird of Passage the climate is comfortable, around +20, even when -20 outside. The 3KW heater keeps the temperature up most of the time but when it goes below -10 outside we turn on an extra 700 W radiator in the deck house. This is the coldest place in the boat, probably due to it's 11 windows. I wonder how it would have been if they weren't double glass ?

Finally, we all wish you a happy good new year and please enjoy the following pictures from Bird of Passage, taken December 29 2009 10 AM in Örebro harbor, Sweden.